We were confronted with the following task:

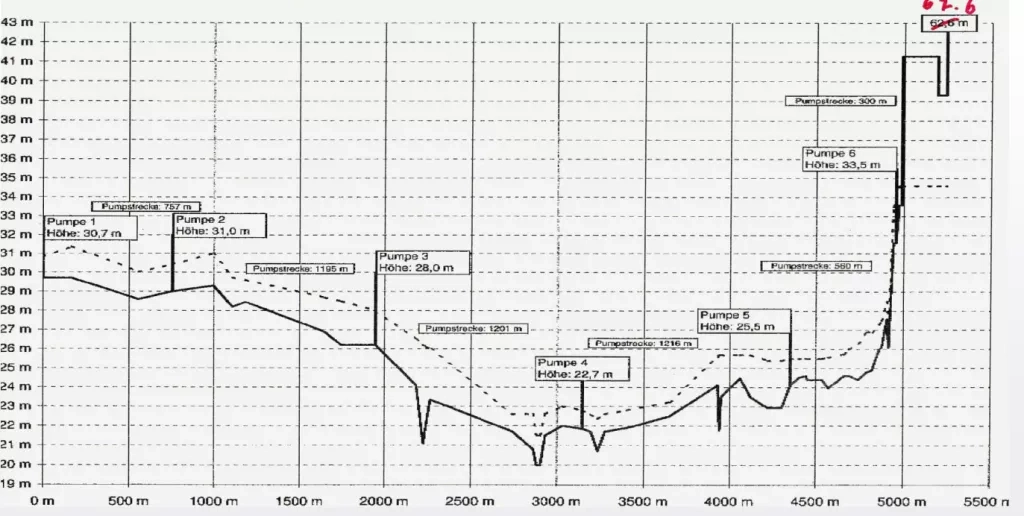

The filling of the storage tanks in the electrolysis plant is necessary up to 4 times a week. Until now, the salt was transferred from an inland vessel to trucks and transported to the electrolysis plant via country roads. About 80 truckloads are needed for one unloading operation. The salt is then transported over a distance of about 12 km. Since the storage tanks have to be filled four times a week, up to 320 truck transports through densely populated areas are required per week. This does not include the empty runs back to the canal. This kind of transport is associated with a lot of noise, dust and exhaust fumes for the residents.

trabajadores cualificados empleados en Habermann Aurum

que habla nuestra empresa para servir a todos los continentes

vida útil media de las bombas de lodo Habermann

es la bomba más antigua de la fábrica

donde nuestras bombas se utilizan a diariamente

como fabricante líder de bombas centrífugas en Alemania

¿Por qué bombas Habermann Aurum?

Habermann Aurum Pumpen es uno de los fabricantes líderes de bombas giratorias para el transporte de líquidos cargados de sólidos. Con casi 100 años de experiencia y la experiencia de más de 30. 000 bombas utilizadas en todo el mundo en una amplia gama de sectores industriales, nos hemos convertido en parte del sistema económico global. Nuestra cartera de productos incluye las áreas de bombas y válvulas. Gracias a la ingeniería interna, también somos capaces de resolver tareas técnicamente exigentes y complejas. Nuestro objetivo fundamental es desarrollar las bombas industriales más duraderas y sostenibles combinando décadas de experiencia con la tecnología más avanzada. Nuestras bombas se utilizan en la minería y la minería, la extracción de materias primas y energía, la siderurgia, la química, la industria de pigmentos, la perforación de túneles y la construcción especializada.

+49 234 / 893570-0

+49 234 / 893570-0 info@aurumpumpen.de

info@aurumpumpen.de